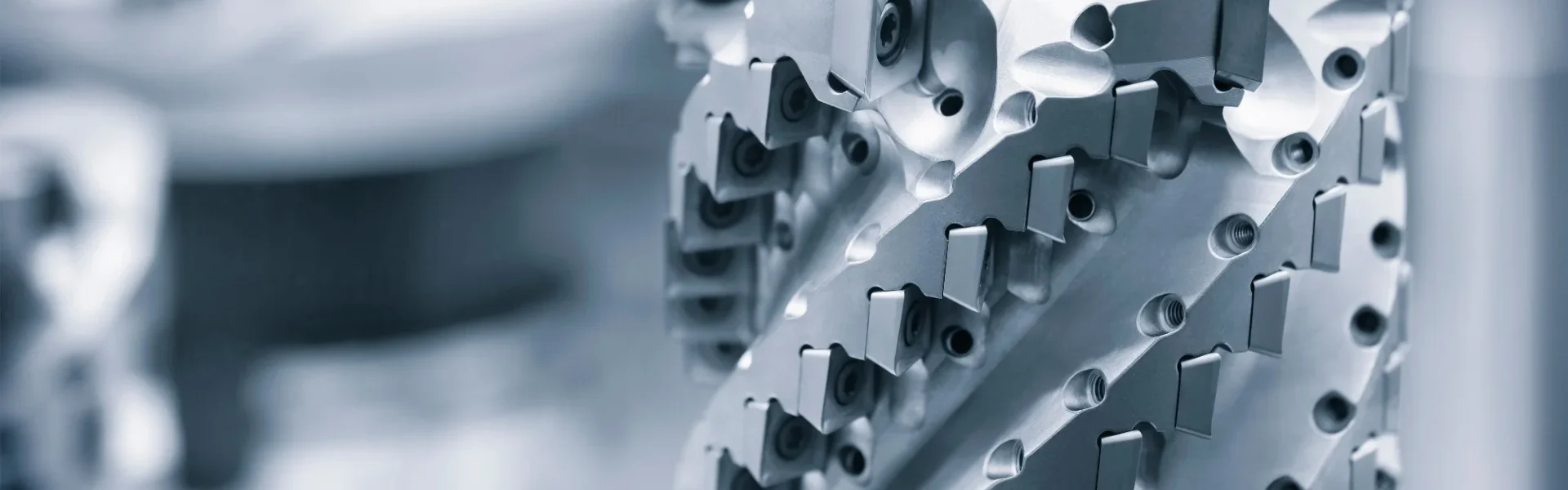

Think about all the things made with precision in factories today. A lot of that precision comes from carbide-cutting tools, allowing workers to shape materials exactly as needed. Made from carbide, a material known for its toughness, these tools withstand high-temperature conditions that would wear out others made of less hardy substances.

Performance gets a boost, and the tools themselves last longer—a benefit for any application. Imagine the savings in replacement costs alone! Whether drilling, milling, or turning operations in automotive or aerospace industries, the right carbide cutting instruments make all the difference.

Exploring Carbide Cutting Tools

Carbide-cutting tools stand out due to their exceptional hardness, drawn from tungsten carbide particles fused with cobalt. This results in a wear-resistant tool that can endure high temperatures and abrasive materials without losing its edge. With this durability comes less frequent replacement needs, ensuring consistent cuts over extended periods.

Consequently, your operations benefit from higher productivity levels as these tools handle greater speeds and feeds efficiently. Superior surface finishes are another hallmark of carbide cutting tools. They provide precise tolerances vital for industries demanding the utmost accuracy, such as aerospace or medical fields.

Plus, they’re versatile across various materials. From aluminum to hardened steel. Which simplifies inventory for diverse machine shops.

In addition to thermal stability under intense heat fostering relentless performance during aggressive machining conditions, you’ll notice lower power usage thanks to reduced force requirements when using carbides compared to traditional HSS options. Over long-term use, these factors culminate in significant savings by slashing production costs per component. This makes them highly attractive investments for manufacturers seeking reliable efficiency gains within a competitive market landscape.

Benefits in Modern Manufacturing

Carbide-cutting tools are pivotal for tackling tough materials that softer metals can’t handle. Micro-grain carbide construction provides these tools with unmatched durability and a longer life span.

- Durability: Solid carbide is exceptionally resilient, standing up to the toughest workpieces where others fall short. These tools from Suncoast Precision are seriously tough. They’re designed to withstand heavy use and keep working, even in the most demanding situations; that’s a promise. You’ll save money and time because this tool is made to last. Consistent performance means fewer replacements.

- Precision: For tasks demanding precise tolerances, solid carbide drill bits maintain accuracy better than their peers. They make clean cuts through hard materials like steel or brass while ensuring hole dimensions stay exact—a must-have when precision is non-negotiable. The quality and structural integrity of the drilled parts aren’t sacrificed; these designs efficiently conquer complex tasks.

- Versatility: Specialty products like solid carbide end mills from Suncoast Precision Tools highlight the adaptable nature of carbide cutting tools. Whether precisely milling aluminum, stainless steel, or hardened materials, these end mills provide exceptional performance across various applications. Carbide end mills make clean, precise cuts in aerospace and medical manufacturing. They’re also incredibly durable, even at high speeds and with tiny details.

Machining pros need reliable tools that last, and Suncoast Precision Tools delivers. Their selection includes variable flute end mills (to reduce chatter), corner radius tools (for extra strength), and high-feed cutters (for efficient material removal)

Enhancing Tool Longevity and Performance

Carbide-cutting tools last longer when properly maintained. You can enhance their longevity by using the correct feed and speed rates, which reduces wear and tear on the tool edges. Regular cleaning after use also prevents buildup that can degrade performance.

For optimal results, store them in a dry environment to prevent rusting or corrosion of the carbide material. Furthermore, applying coolant during operations not only lowers temperatures but also minimizes friction—a leading cause of early tool degradation.

It’s critical you choose compatible coolants, as some chemicals might damage your tools rather than protect them. Lastly, routinely check for dullness and re-sharpen promptly to maintain cutting efficiency; this ensures sharpness without compromising structural integrity.

Applications Across Industries

Carbide-cutting tools serve a crucial role across various sectors, offering precision and durability. In aerospace, they machine alloys for aircraft parts with high accuracy. The automotive field depends on them to produce critical components such as engines and transmissions consistently.

With these tools’ versatility in working with materials like aluminum, brass, or stainless steel, industries from woodwork to composites benefit by ensuring precise cuts and efficient operations. Attributes are directly linked to increased productivity levels. These tools’ wear resistance means fewer replacements and more savings over time.

A significant factor contributing to their adoption in CNC manufacturing processes where quality can’t be compromised. As manufacturers pursue optimal performance while minimizing costs, solid carbide cutters have become indispensable assets within industry tooling inventories

Selecting the Right Carbide Tool

- Tool Material Selection: Consider the material you’re cutting when choosing carbide tools. Tough materials demand stronger, more durable tips like those found in carbides. They manage heat and wear better than high-speed steel, ensuring a longer life for your tooling.

- Understanding Coatings: Carbide cutters can have special coatings that extend their lifespan and enhance performance on specific materials. These layers minimize friction and improve chip flow during machining tasks, leading to cleaner cuts and higher precision jobs.

- Geometric Considerations: Various shapes of cutter geometries are purpose-specific; they impact how forces are applied to both workpiece and tool alike, while machining is conducted with consistent results guaranteed only if matched correctly—square ends for keyways or ball noses for contouring profiles.

Innovations in Carbide Technology

Carbide technology has revolutionized precision manufacturing with its extraordinary strength and durability. You benefit from increased accuracy in aerospace and medical industries where tight tolerances are the norm. These tools cut cleaner, reducing extra finishing steps.

They also last longer than high-speed steel options, staying sharp through rigorous use. This minimizes your downtime for tool changes; productivity stays high. Operating at greater speeds without compromising on performance lets you remove material faster, shortening production cycles crucially in volume-driven setups.

Your initial cost may be higher but think of the long-term savings: fewer replacements plus less maintenance equals a lower total cost over time. In automotive and electronics, carbide-cutting tools ensure parts meet exact standards consistently. Think engine blocks or complex circuit boards.

All while bolstering efficiency across all stages of your operation. Whether it’s machining turbine blades in aerospace or creating precise dental implants, these tools enable fine detailing necessary for top-tier products even under substantial wear conditions—an undeniable asset for quality-focused manufacturing sectors looking to maintain an edge.

Carbide-cutting tools are critical in manufacturing due to their strength and durability. Made from a compound of carbon and tungsten, they retain sharp edges at high temperatures, which ensures precision cuts on tough materials where other cutters falter. They boost productivity by minimizing downtime for replacements, making them vital for efficient operations.

Suncoast Precision Tools offers top-quality carbide end mills suited for various machining tasks to keep your production moving smoothly and reliably day after day.