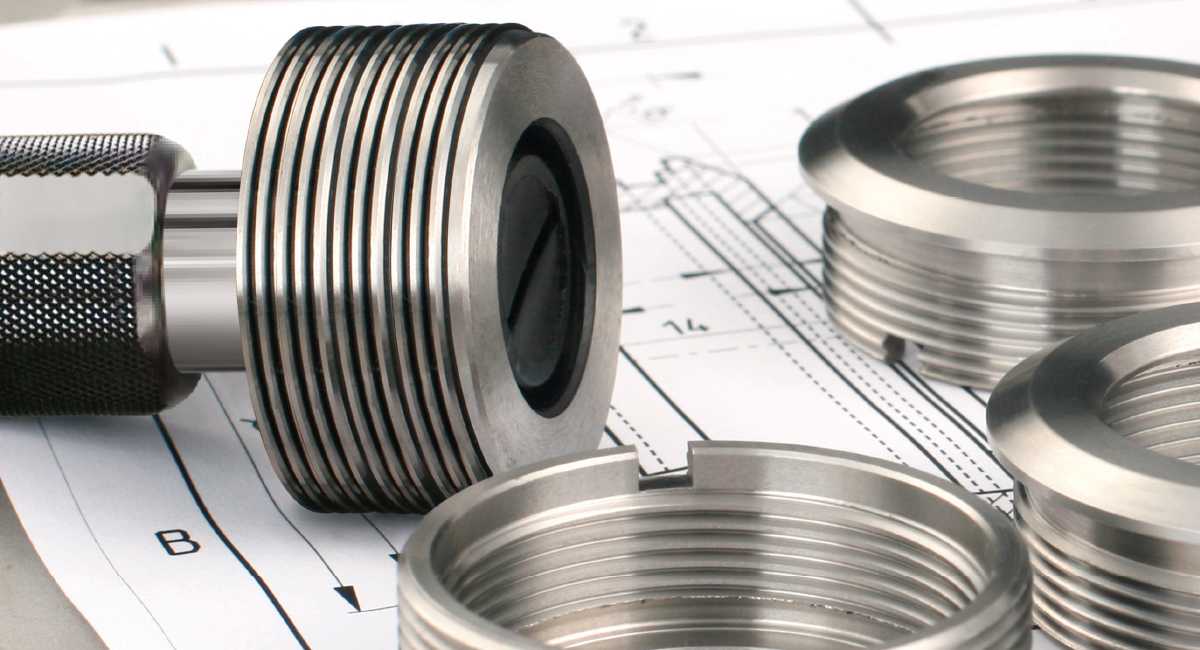

Precision and accuracy are of paramount importance in the manufacturing industry. Thread gauges such as Metric thread gauges play a pivotal role in ensuring that the nuts and bolts of various industries fit together seamlessly. However, like all tools, thread gauges have a lifespan, and understanding when to replace them and how frequently to source new ones is crucial for maintaining the quality and efficiency of production processes.

Thread gauges serve as the standard by which threaded parts are measured, guaranteeing that they conform to precise specifications. Over time, these gauges can wear out due to repeated use and exposure to harsh environments. The wear and tear on thread gauges is gradual and may not always be immediately visible, making it challenging to determine when replacement is necessary. To address this, manufacturers must implement a comprehensive inspection and maintenance program.

Regular examinations of UN thread gauges are imperative for spotting early indications of wear or harm. This entails a thorough scrutiny of the gauge’s threads, with a focus on maintaining their sharpness and integrity. Any deviation from the anticipated dimensions or the presence of wear indicators, such as nicks or burrs, should prompt deliberation regarding replacement. Furthermore, the inspection protocol should encompass calibration assessments to guarantee the gauge’s sustained delivery of precise measurements.

The frequency of gauge replacement depends on several factors. One crucial factor is the intensity of use. Thread gauges subjected to heavy usage will wear out more quickly than those used sparingly. Consequently, industries with high-volume production may need to replace gauges more frequently. In contrast, low-volume operations may find that their gauges last longer before replacement is necessary.

The replacement frequency of thread gauges is influenced by environmental factors. When thread gauges are exposed to corrosive substances or extreme temperatures, their deterioration tends to accelerate. While regular maintenance and cleaning can help prolong the lifespan of gauges in these challenging conditions, it is important to acknowledge that replacement may still become necessary earlier compared to less severe environments.

Another crucial consideration lies in the material and quality of the thread gauge. Thread gauges crafted from high-quality, durable materials tend to exhibit a longer lifespan. Despite their potentially higher upfront price tag, their extended longevity often renders them a cost-effective choice in the grand scheme of things. On the flip side, opting for cheaper, lower-quality gauges may necessitate more frequent replacements, essentially nullifying any initial cost savings.

Undoubtedly, the significance of precision in manufacturing cannot be emphasized enough. Thread gauges serve as indispensable instruments in guaranteeing that products align with industry standards and meet the expectations of customers. Consequently, the replacement of gauges should not be postponed when they exhibit signs of wear or inaccuracies. Continuing to use worn or damaged gauges can result in products that fall outside of specifications, leading to rework, potential defects, and the potential for substantial costs and harm to a company’s reputation.

Sourcing new thread gauges should be a well-planned process. It involves not only selecting the right type and size of gauge but also choosing a reputable supplier.