In the world of production lines and manufacturing, the fluidity of operations often hinges on the seemingly simple yet intricate process of liquid filling. It’s in this niche that a company like Volumetric Technologies shines, offering advanced solutions that revolutionize how businesses approach the task of filling containers with various liquids.

At the core of every successful production line is not just the quality of the product but the efficiency and precision with which it’s packaged. This is where the importance of an outstanding liquid filler machine becomes undeniable. Among the myriad of options available in the market, Volumetric Technologies has emerged as a beacon of excellence. Their state-of-the-art filler machines are meticulously designed to cater to the multifaceted demands of modern businesses, ensuring they stand a notch above the rest.

Unlocking the Future of Liquid Filler Technology

Accuracy and Efficiency in Liquid Filling Equipment

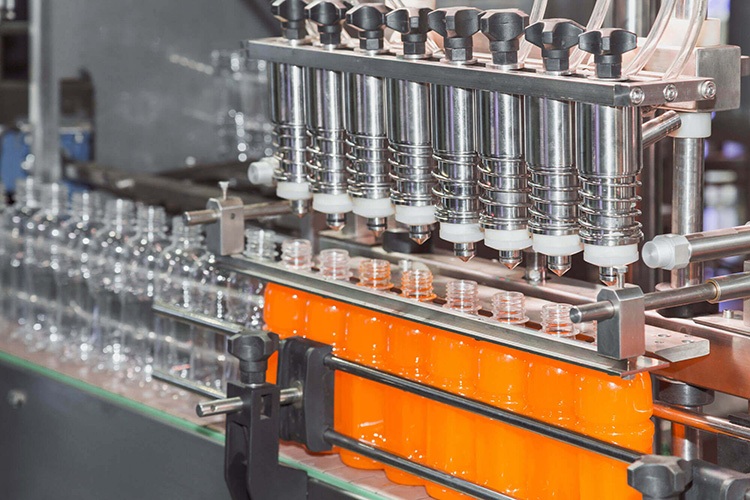

When discussing top-tier liquid filling equipment, two critical aspects come to the forefront: accuracy and efficiency. Volumetric Technologies has mastered these facets, crafting machines that promise consistent, precise filling. This precision is paramount as it minimizes waste and ensures uniformity in product volume across the board. It’s the company’s unwavering commitment to precision that sets their machines apart, making them an unmatched ally in the quest for operational excellence.

Adaptability and Customization

Adaptability and customization are also at the heart of Volumetric Technologies’ offerings. The capability to accommodate various product consistencies, packaging types, and production scales is what makes their machines truly standout. They’re engineered for versatility, ensuring businesses can swiftly adapt to changing demands without skipping a beat. Whether scaling up production or shifting to different container sizes, these machines provide a seamless transition, showcasing unmatched flexibility.

User-Friendly Design

Ease of use is another cornerstone of Volumetric Technologies’ approach. Understanding that the complexity of operation can impede productivity, their liquid fillers are designed with user-friendly interfaces. This attention to operational simplicity reduces the likelihood of operator errors and boosts overall efficiency and productivity.

Ensuring Cleanliness and Hygiene

In industries where cleanliness and hygiene are non-negotiable, such as food and beverage, pharmaceuticals, and cosmetics, the design of a liquid filling machine takes on even greater importance. Volumetric Technologies’ machines are expressly created with these sectors in mind. They prioritize ease of maintenance and the utmost purity, safeguarding against contamination and ensuring products meet the highest safety standards.

Investing in Longevity and Performance

Choosing a durable, reliable liquid filling machine is an investment in a business’s future. Volumetric Technologies underscores this principle by offering machines that are not just built to last but also designed for minimal maintenance. This proactive approach to durability translates to fewer operational interruptions and an extended machine lifespan, delivering tangible cost savings over time.

The evolution of automated features and the ability to seamlessly integrate into existing systems are defining traits of an exemplary filler machine. Volumetric Technologies excels in this domain, crafting products that augment efficiency and productivity. These advancements keep businesses ahead of the curve, ready to meet the dynamic needs of the marketplace.

Choosing Excellence with Volumetric Technologies

Volumetric Technologies stands at the leading edge of liquid filler machinery and is known for its precision and high-caliber performance. The goal is clear: to provide meticulously engineered machines that resonate with the diverse requirements of producers across various industries.

Enhancing Production Through Innovation

From minimizing waste to optimizing productivity for a wide range of applications and container specifications, their machines embody a commitment to maximized efficiency and cleanliness. They exceed industry standards, guaranteeing a highly effective and sanitary production environment.

Key Features for Optimal Performance

Moreover, these fillers are applauded for their reliability and effortless integration, ideal for continuous operation with low maintenance demands. Their advanced automation capabilities ensure a smooth inclusion in manufacturing lines, delivering consistency and top-quality performance.

The Advantages of Partnering with Volumetric Technologies

Opting for a liquid filling solution from Volumetric Technologies means choosing efficiency, adaptability, and reliability. It represents a commitment to enhancing production processes and boosting productivity, ensuring access to innovative, dependable machines that lead to accuracy and efficiency.