From towering skyscrapers to robust bridges, these structures rely on the synergy between concrete and steel reinforcement bars (rebars) to withstand time and nature’s forces. As buildings grow taller and infrastructure projects become more complex, a seemingly simple component has gained significant importance – the rebar coupler.

Evolution of rebar splicing

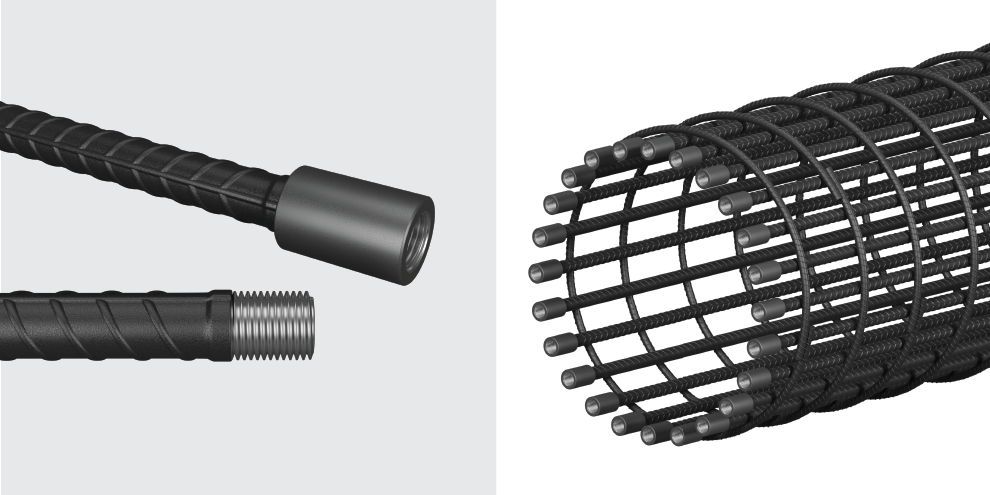

Historically, reinforced concrete structures relied on lap splicing. This method involves overlapping the ends of two bars for a specified length, typically 30 to 40 times the bar diameter. While effective, lap splicing has its limitations, especially in modern construction scenarios. As we push the boundaries of structural design, the need for more efficient and reliable rebar connection methods becomes apparent. This is where rebar couplers step in, offering a host of benefits that address traditional splicing shortcomings.

Future of rebar couplers

- Advanced materials – Development of couplers using high-performance materials that offer greater strength and durability.

- Smart couplers – Integration of sensors within couplers to monitor structural health and detect potential issues in real-time.

- Simplified installation – Innovations aimed at making the installation process faster and more foolproof, reducing the skill level required for proper use.

- Sustainability – Exploration of more sustainable materials and manufacturing processes for coupler production, aligning with the growing focus on green construction practices.

Advantages of rebar couplers

- Space efficiency – In congested reinforcing bar couplers areas, such as beam-column joints or foundation elements, lap splices create significant congestion, making it challenging to place and compact concrete properly. Rebar couplers eliminate long overlaps, reducing steel congestion and allowing for more efficient use of space within the concrete member.

- Structural integrity – Rebar couplers are designed to develop the full strength of the joined bars, ensuring a continuous load path through the connection. Many modern coupler systems achieve 100% of the specified yield strength of the rebar, and some even exceed it. This level of performance is particularly crucial in seismic regions or in structures subject to dynamic loads, where rebar connections are paramount.

- Time and cost savings – While rebar couplers may be more expensive than traditional lap splicing, they often lead to significant time and cost savings throughout a project. By reducing the amount of rebar required and simplifying the assembly process, couplers speed up construction timelines and reduce labour costs. In high-rise buildings, where every floor requires splicing, these savings are substantial.

- Versatility in construction – Rebar couplers offer increased flexibility in construction sequencing and phasing. They allow for easier connection of precast elements to cast-in-place concrete, facilitating hybrid construction techniques.

- Quality control – Rebar couplers can improve quality control on construction sites. Unlike lap splices, which rely on proper positioning and concrete placement for effectiveness, mechanical couplers provide a more consistent and reliable connection. Many coupler systems also offer visual or tactile indicators of proper installation, reducing errors.

- Enhanced durability – In corrosive environments or structures with a long design life, rebar couplers contribute to enhanced durability. Some coupler systems are designed with corrosion-resistant materials or protective coatings, maintaining reinforcement integrity over time. This is particularly critical for marine structures, bridges, or other infrastructure exposed to harsh conditions.

- Reduced concrete requirements – By eliminating long lap splices, rebar couplers can reduce the overall dimensions of concrete members. This not only saves on material costs but also leads to lighter structures, which is beneficial in both seismic design and foundation engineering.