Connectivity is at the heart of modern technology, enabling seamless communication and power delivery across various applications. In the realm of robust and reliable connectivity, Mil grade connectors play a crucial role. These connectors are designed to meet stringent requirements and withstand harsh conditions, ensuring uninterrupted performance in critical operations. To appreciate their importance, it is essential to understand their essential components.

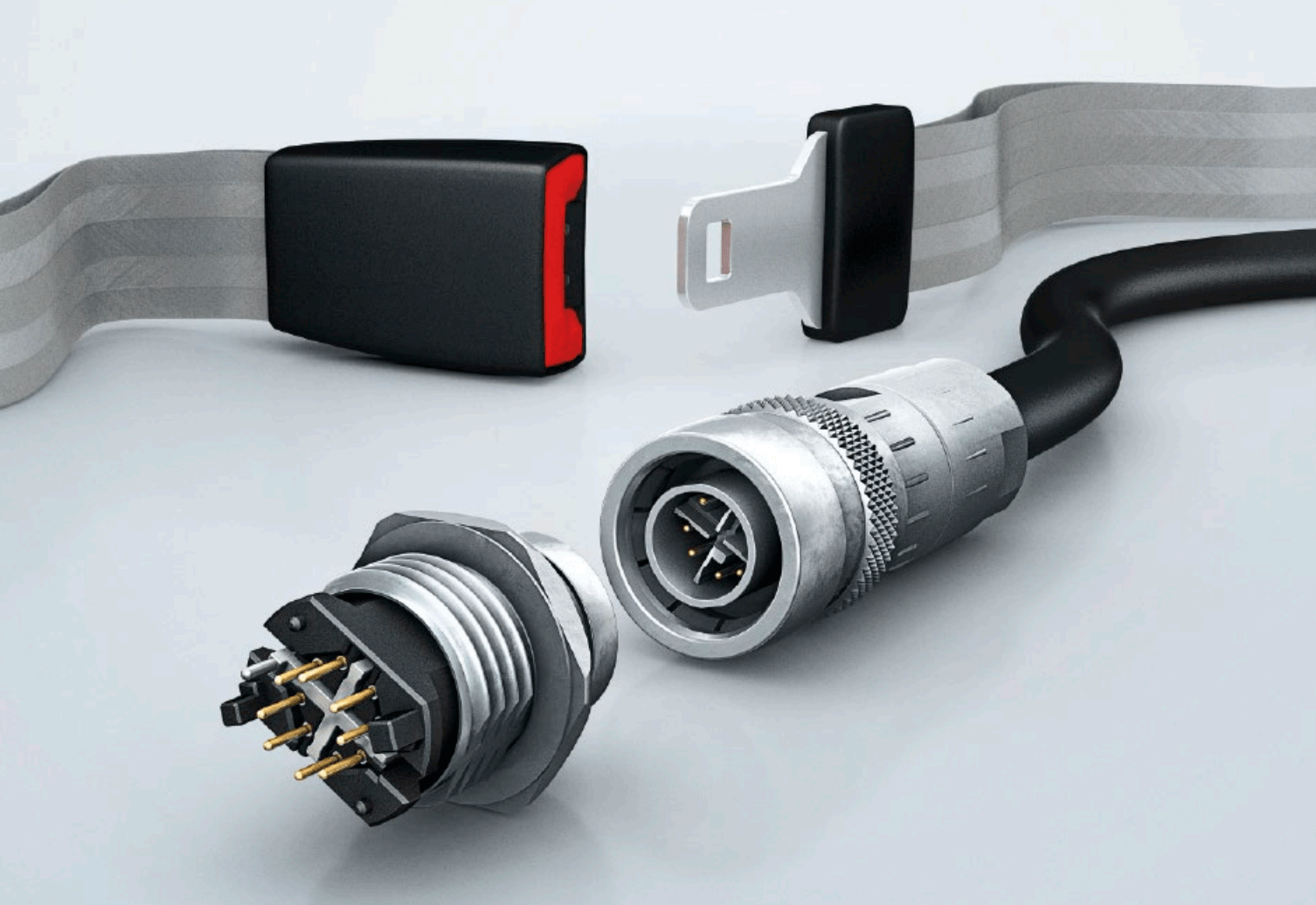

Shell

The connector’s shell serves as its outer protective cover. It is usually made of durable metals such as stainless steel, which offer durability and resistance to corrosion and environmental hazards. The shell provides mechanical strength and protects internal components from physical damage. Additionally, it facilitates proper mating and alignment of connectors, ensuring a secure and reliable connection even in challenging environments.

Contact pins

Contact pins are conductive elements within connectors that establish electrical connectivity. These pins are manufactured to carry current and transmit signals reliably. They are made of high-conductivity materials, such as copper or gold-plated copper, to reduce signal loss and ensure optimal power transmission. The quality and accuracy of the contact pins have a significant impact on the overall performance and integrity of the connector.

Insulators

These are non-conductive components that separate contact pins within a connector. They prevent electrical short circuits and ensure proper isolation between adjacent pins. Insulators are usually made of strong materials such as thermoplastic or ceramic, which have excellent dielectric properties. These materials can withstand high temperatures and voltages, provide insulation, and maintain electrical connection integrity.

Backshells

These are protective covers or enclosures placed over the connector’s cable or wire termination area. They provide strain relief and shielding for cables, ensure proper cable management, and enhance mechanical stability. Backshells also protect against electromagnetic interference (EMI) and radio frequency interference (RFI), which degrade electrical signals. They are generally made of metal or composite materials for strong protection and grounding.

Grommets and Seals

They are located around the connector’s cable or wire entry point to ensure a waterproof and dust-proof connection. Grommets and seals are typically made of elastomers or rubber materials, which provide flexibility and resistance to environmental elements. They play a vital role in maintaining internal components’ integrity, especially under harsh and challenging conditions.

Coupling Mechanism

It ensures a reliable and strong connection that withstands vibration and mechanical stress. Mil-spec connectors employ various coupling mechanisms, such as threaded, bayonet, or push-pull couplings. The specific coupling mechanism depends on the application requirements and the level of security and stability required.

Keying and Polarization Features

These are incorporated into the connectors to ensure proper alignment during connection. Keying involves using a unique keyway or slot on the connector shell with a corresponding key or keyway on the mating connector. This design prevents misconnection and ensures proper pin and contact alignment. Polarisation features enhance optimal mating by connecting connectors in only one orientation, eliminating misconnections.

EMI/RFI Shielding

Mil grade connectors often include additional electromagnetic interference (EMI) and radio frequency interference (RFI) shielding features. These features, such as metal shielding or conductive coatings, provide additional protection against unwanted RF radiation or interference. EMI/RFI shielding maintains signal integrity and ensures reliable data transmission in high electromagnetic-noise environments.